Best 3D Printer

There are loads of 3D printers on the market these days, which also means there are hundreds of imitators of the big brands, potentially scamming you out of your money and spoiling your 3D printing dreams before they’ve even begun.

Never fear! We’ve got a list of five for you to check out, targeting a variety of needs, wants, and budgets. There’s bound to be at least one gadget you can treat yourself to, so get scrolling and figure out which one it is!

Products at a Glance

Best 3D Printer

- Large build area

- Fast curing times

- ChiTuBox Slicer

- Cooling fans are loud

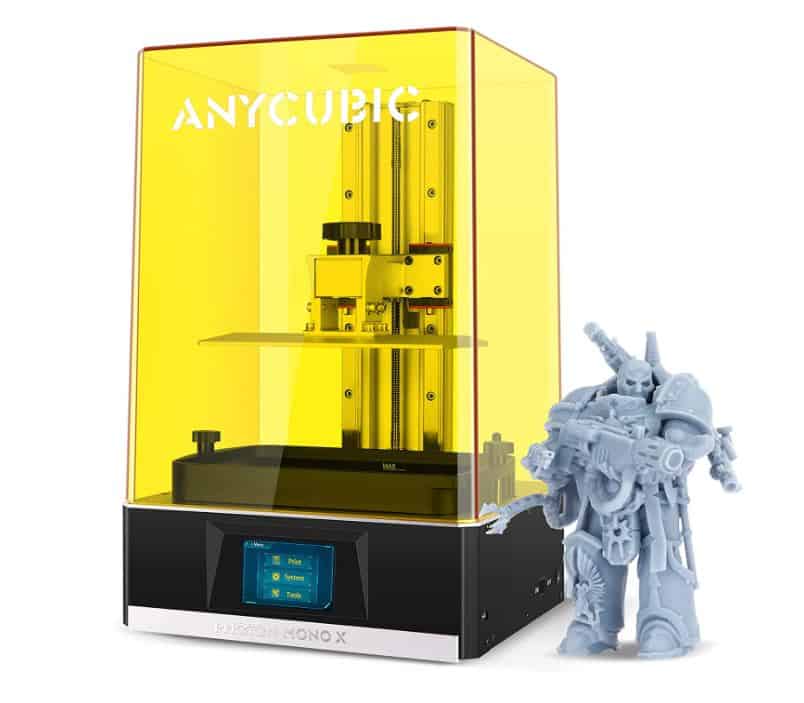

Offering faster printing for less maintenance, the Elegoo Mars 2 is an affordable yet high-quality printer with its own HD screen and a far greater lifespan thanks to its Mono LCD technology, which is efficient and performs well.

Supporting over twelve different languages and housed inside a CNC machined aluminum body, the outstanding prints produced by its UV laser and 2K mono LCD are ultra-accurate. Not convinced? Thankfully there’s a one-year warranty!

- Fast printing speed

- Closed printing area for cleaner prints

- Easy to setup and use

- Expensive 3D printer option

Transforming your 3D designs into tangible objects, the FlashForge Dreamer boasts dual extruder nozzles inside an enclosed chamber, so you get faster prints that are insulated and protected from potential external damage.

Its hard-wearing, plastic alloy body has an integrated HD IPS touch screen, and the unit also comes with the manufacturer’s FlashPrint software, as well as being fully compatible with the Slic3r slicing program. You get what you pay for here!

- Ability to mix different coloured filament

- Replacement parts are easy to find

- Well priced for a dual-extrusion printer

- Filament spool holders is not well designed

Assembled in just twenty minutes, Geeetech’s dual nozzle 3D printer delivers four kinds of printing: single color, double color, graded color, and mixed colors, allowing for the ultimate in experimental design for visual artists and modelers.

Coming with its very own GT2560 V4.1b Marlin Control Board and firmware, the entire unit is easy to operate and performs beautifully, including an integrated auto-leveling function. It’s on the cheap side, but there’s no compromise on quality!

- Magnetic heat bed

- Filament runout sensor

- Resume printing function

- Manual bed leveling

Supporting multiple languages via its TFT touch screen, the BIQI B1 utilizes a variety of advanced technology to deliver an FDM printer you won’t regret investing in. Its very own magnetic patch allows for easy removal of models every single time!

One exceptionally cool feature is that in the event of a power outage, the last recorded extruder position will be assumed and printing will resume right from where you were, minimizing waste and saving you time starting from scratch.

Buyer’s Guide

With 3D printers, the possibilities of what you can create are endless. You can create everything from your own custom phone case to musical instruments.

As you can see from our above selections too, there are plenty of 3D printers out there to choose from. But before you buy one, there are a few important aspects to consider, such as what you will be using the printer for, what materials and equipment you’ll need, and, most importantly, safety.

Materials

The two materials used for 3D printing are Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS). These are thermoplastics that soften and become malleable when heated, or freeze when cooled. They are sold as 2.2lbs spools of filament and usually cost around $30.

PLA: A plastic derived from corn starch, PLA is excellent for beginners and is great for creating small, simple household items. It is also biodegradable and cools quickly, and is available in solid and translucent colors. However, its low melting point may cause models to deform in high temperatures, and is difficult to work with if you require joints and interlocking parts.

ABS: A petroleum-based plastic, ABS is popular due to its strength and flexibility. It also has a higher melting point, making your creations less likely to deform under high heat. However, it does take longer to cool than PLA, and models are prone to warping. It also emits fumes during printing.

So which one to choose? Well, you need to know which material is suitable for your final product and then you’ll know what type of printer you should buy. Keep in mind that not all printers will accept both materials, some will only work with one type.

Whether 1.75mm or 3mm in diameter, filament size doesn’t matter. It won’t affect the overall quality of the end product. However, most popular printer brands accommodate 1.75mm so we would recommend that.

Safety

There are three main safety concerns with 3D printing – heat, fumes, and plastic.

Heat: Always keep in mind that you are working with heated plastics. Extruders, plastics, and even the print bed itself can get very hot and can lead to severe burns if you are not careful. Also, some printers have no enclosure around the print area, so be extra careful when using these printers.

Fumes: You should always keep your 3D printer in a well-ventilated room. We have already mentioned that ABS plastic emits fumes during printing, and can be quite overwhelming. However, no research states it has an impact on general health. But if you plan on using your printer a lot, it is good practice to take the necessary precautions.

Food-grade plastic: While you can use 3D printers to create pretty much anything, it is advised to hold back on creating kitchenware with them. While ABS and PLA are generally food-safe, any additives added in may not be. Also, products created with FDM-type 3D printers have porous surfaces which bacteria can collect in.

Obtaining a 3D Model

There are two ways to get a 3D model. You can either create it yourself or download a pre-made model blueprint.

There is a variety of software out there to create your own model, both free and commercial, and plenty of resources available to learn 3D modeling.

Learning to model in a computer is a fairly difficult task though, that takes a lot of practice and time. But if time is not on your side, there are plenty of websites that provide models of many different items.

What is the right volume for a 3D printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. The smallest build volume of any 3D printer is usually 3.9 by 3.9 by 4.9-inches. Medium printers are usually 10 by 10 by 10-inches, and any printer with at least one build dimension of more than 10-inches is considered large.

Usually, budget-friendly 3D printers have small build volumes, while more expensive ones tend to be larger. But this also depends partly on the type of printer. Closed-frame 3D printers tend to have small build volumes, while open-frame printers (that are not as sturdy) often have relatively large build volumes. Importantly, the right build volume will depend on what you want to print.

Should I get an open-frame or closed-frame 3D Printer?

Closed-frame 3D printers are boxlike devices with a rigid base, walls (with a transparent door at the front), and top. They muffle noise, reduce odor from any melted filament, and they are safer if you have any children or pets around who might accidentally touch the hot extruder. However, they are smaller than open-frame printers.

Low-cost 3D printers are available in both open-frame and closed-frame models. If you’re after a larger build volume, then you may get more value for money with an open-framed model. However, they tend to be noisy, emit odors when certain plastics are melted, offer little protection, and some may require assembly and more maintenance to keep them running smoothly.

What should I look for in 3D printer software and connectivity?

3D printing software performs three main functions. It processes an object file (moving, rotating, resizing, and duplicating it), slices it (into virtual layers), and finally, prints it. This is almost always universally combined into a seamless process. Some high-end printers have software that supports an even wider range of settings.

Connection options from model to model may vary with cheaper sets, however. They almost all have a USB Type-A port to fit a thumb drive for printing from document files, and a USB Type-B port for connecting directly to a computer. Some also offer Wi-fi as an alternative, and some even let you connect via Ethernet to share a printer across a local network.

Some printers let you store 3D files on an SD or microSD card. Most 3D printer manufacturers (even budget-friendly ones) have a mobile app to launch and monitor print jobs, and some let you access cloud services for you to print from.

Our Verdict